Adjust the Float Rod

The sturdy plastic and rubber constructions provide energy and durability, which allows for optimum efficiency for traditional single-flush applications. With an easy-to-install and universal design, Korky QuietFill is considered one of the good replacements for noisy, old, and damaged ballcocks in your 2-piece and 1-piece bathrooms. To change how a lot water flows into the toilet tank, you bend the brass rod both up to raise the water level, or downwards to decrease the water degree. Keep in thoughts that you must keep the water level within a given most level.

When to Adjust Your Toilet Float

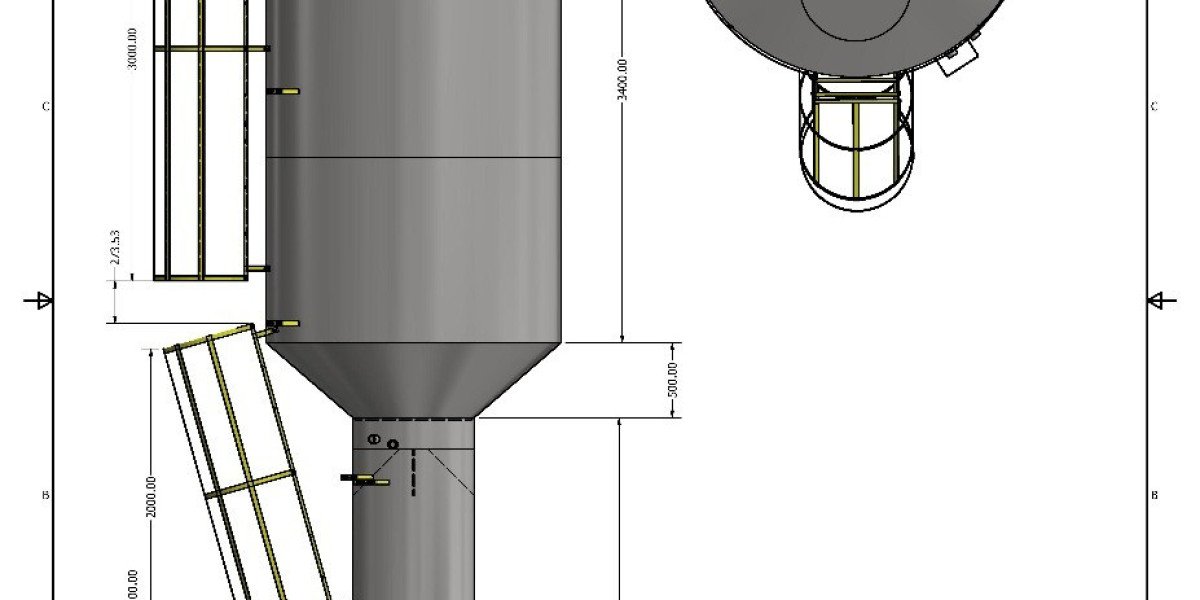

Aquamate Commercial Water Tank Brochure

If your business requires safe storage of fuel and other inflammable liquids, then it’s essential to make use of an industrial gas storage tank. Industrial gasoline storage tanks are requirements licensed containers which provide protected storage of chemical compounds, solvents, oil, petrol, diesel, and different hazardous and flammable liquids. Fuel storage tanks prohibit evaporative emissions as nicely as prevent any leakage of the substance contained in it. An industrial gasoline storage tank has the power to carry a selection of inflammable liquids. If your storage needs are very specific, inform your manufacturer about them since they might customize or adjust tank specifications and models in order to meet your special necessities. Some of the fashions are moveable too to permit straightforward relocation when essential. Corrugated steel liquid storage tanks are versatile, sturdy, economical, and have a good longevity.

Aquamate 5,000 US Gallon CA5000 Water Tank Specification

The maximum diameter of our vertical tanks is 12 feet with a maximum shell top of 35 toes if UL 142 and 12 toes by forty five feet if API 650. Aquamate large steel water tanks, from 5,000 gallons to 102,000 gallons, can be found by way of our authorized sellers. All of our tanks are put in by Aquamate educated and certified technicians, which means you'll find a way to be positive that your steel water tank will stand the check of time. Most of the gases are offered inside fuel cylinders and a few gases are bought within the type of liquid inside appropriate containers or within the form of bulk liquid that’s delivered by truck. Originally, the industry supplied gases inside cylinders to forestall any necessity for technology of fuel locally. Plastic tanks are constructed on the premise of the liquid type to be stored.

When the water strain increases to a preset amount—based on the extent of water within the tank—the valve shuts off the water. From the normal float-ball valves to the more compact and environment friendly fashionable techniques, the choice of valve can significantly impact a toilet’s performance and water effectivity. Understanding the various sorts of fill valves is essential as they play a job in the performance and sustainability of the entire plumbing system. There are two primary kinds of valves – the flush valve and the fill valve. They work in tandem to ensure the system operates effectively, filling and emptying water as wanted for every flush. When the float reaches a sure top, the outlet valve opens, and the inlet closes. This permits water to flow into the bathroom tank and cease when the floating ball reaches its highest point.

Diaphragm-Type Ballcock Fill Valve

Replace a damaged fill valve in a water-saver rest room with a brand new Fluidmaster 3-inch Fill Valve Kit. It comes with an oversize rubber flapper for toilet tanks with 3-inch flapper drains. This common rest room fill valvekit features adjustable valve top to regulate the quantity of water within the tank. Fortunately, a few kinds of dependable bathroom fill valvesare obtainable. Many are common, that means they'll substitute the identical fill valve type that’s in the toilet now, even when the toilet model is completely different. Different manufacturers provide numerous designs, meaning flush valves are not common.

How Pressure Tanks Maintain Water Supply