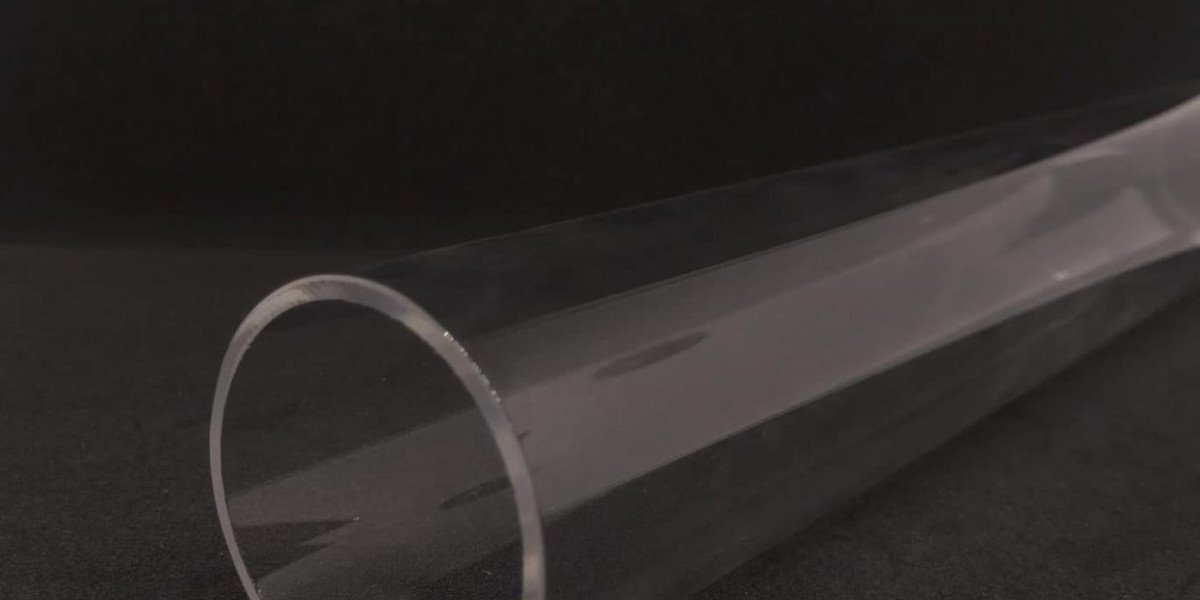

Quartz tubes are made from high-purity silica, which gives them exceptional thermal stability and resistance to extreme temperatures. These tubes are widely used in scientific, industrial, and manufacturing applications where heat resistance is critical.

Key Benefits of Quartz Tubes

1. Exceptional Heat Resistance

Qartz tube can withstand extremely high temperatures, often exceeding 1000°C (1832°F) without deforming or melting. This makes them ideal for furnace applications, laboratory equipment, and high-temperature processing.

2. High Purity and Chemical Resistance

Quartz is chemically inert, meaning it does not react with most acids, bases, or other chemicals. This makes quartz tubes a great choice for laboratories, semiconductor production, and chemical processing.

3. Superior Thermal Shock Resistance

Unlike many other materials, quartz can rapidly heat and cool without cracking, making it highly reliable in temperature fluctuation environments.

4. Excellent Optical Clarity

Quartz tubes are often transparent or translucent, allowing for precise monitoring of reactions, laser transmission, and optical applications.

5. Electrical Insulation Properties

Quartz is an excellent electrical insulator, making it ideal for electronic and semiconductor industries where high-voltage insulation is required.

Common Uses of Quartz Tubes

Industrial and Laboratory Applications

Quartz tubes are widely used in furnaces, kilns, and high-temperature reactors due to their thermal and chemical stability.

Semiconductor and Electronics Industry

Because of their purity and insulating properties, quartz tubes play a crucial role in semiconductor manufacturing, fiber optics, and electronic components.

Medical and Scientific Research

Quartz tubes are used in diagnostic instruments, UV sterilization, and advanced research applications where high precision and durability are essential.

Lighting and Optical Applications

Many high-intensity lamps, lasers, and UV sterilization systems use quartz tubes because of their optical clarity and heat resistance.

How to Choose the Right Quartz Tube

1. Size and Thickness

Quartz tubes come in various diameters and thicknesses, depending on the intended use. Thin-walled tubes are suitable for optical and electronic applications, while thicker tubes are preferred for industrial and high-stress environments.

2. Purity Levels

High-purity quartz offers better resistance to thermal and chemical degradation, making it ideal for demanding applications such as semiconductor processing.

3. Surface Finish and Clarity

Some applications require polished or transparent quartz, while others may work best with frosted or opaque finishes.

4. Custom Fabrication

Manufacturers offer custom-cut quartz tubes tailored to specific project requirements, ensuring optimal performance and efficiency.

Where to Buy Quartz Tubes

Quartz tubes are available from specialty glass manufacturers, scientific supply stores, and industrial suppliers. When purchasing, consider factors such as size, purity, and delivery options.

Conclusion

Quartz tubes provide exceptional heat resistance, chemical stability, and optical clarity, making them an ideal choice for high-temperature applications. Whether you need them for industrial, laboratory, medical, or electronic uses, quartz tubes offer reliable performance and durability.